Piercing Drilling

Request a Quote

Piercing Drilling in Seattle, WA, and the Nearby Areas

At Full Trenchless, one of our specialized services is horizontal directional drilling (HDD)—a highly effective solution when obstacles make utility line installation challenging. This proven trenchless technique is widely used by gas, water, and electric industries for everything from “street-to-house” connections to last-mile pipe installations.

For projects requiring pipe installations under 300 feet, our technicians utilize compact drill machines designed for precision and efficiency. As HDD continues to grow in demand across industries, our team combines expertise with advanced piercing tools to deliver reliable results.

We specialize in installing smaller diameter pipes in compressible soils with minimal excavation required for rig retrieval or launch. With this approach, our crews can install pipes up to 100 feet, making it the ideal method for utility installations beneath existing structures, roads, and landscapes—without disruption.

Our team services homes and businesses in:

Seattle, WA

Tacoma, WA

Bellevue, WA

We also offer sewer, pipe, and drain solutions to other locations, including

Redmond, WA

Renton, WA

Everett, WA

Issaquah, WA

A Less Disruptive Alternative To Trenching

The problem with traditional digging is that it tears up landscapes and leaves behind a much larger footprint compared to modern trenchless technology. At Full Trenchless, we use advanced pipe piercing methods with pneumatic tools to create a precise, compact hole.

This approach allows contractors to install utility lines without the hassle of above-ground obstructions—whether that’s lawns, buildings, streams, parking lots, driveways, or roads. With this efficient process, we can install cable, electrical, fiber optic, water, and underground gas lines beneath streets, properties, and yards—all while minimizing disruption to traffic, property, and the environment.

The result? Less mess, less clean-up, and a project completed with speed and precision.

full Trenchless Pipe Piercing Technology

At Full Trenchless, our piercing drilling process in Seattle, WA is both simple and highly effective. We size the piercing tool to match the desired hole diameter and then create entry and exit pits about 10 times the tool’s size. For example, a 3-inch tool would require a 30-inch pit. Once the pits are prepared, our skilled technicians connect compressor hoses to power the piercing tool, which is then positioned at the entry pit, leveled to the ground, and aligned with the exit point.

The tool is propelled by compressed air, boring from entry to exit along the planned path. After the bore is complete, we install the piping conduit into the new hole. Under ideal conditions, production averages one foot per minute, with bore sizes ranging from 44 mm to 203 mm (1.75 to 8 inches) and lengths up to 15 feet (15 m). For longer installations, we use a method called stitching.

Stitching involves multiple shorter bore shots (typically less than 50 feet each), which lets our crew safely locate utilities while excavating launch pits simultaneously. This approach is not only accurate and cost-efficient but also boosts overall productivity. For example, a 4-person crew can install over 400 feet of pipeline per day—including excavation and restoration—while keeping labor costs under control.

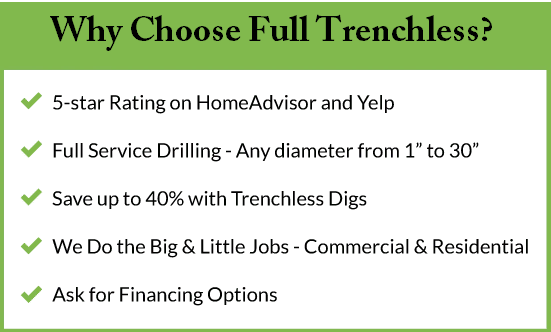

Work with Your Trusted Pipe Experts at Full Trenchless

At Full Trenchless, you can count on our attention to detail and top workmanship to complete services efficiently. Our drilling company has the tools, the equipment, and the drilling techniques and skills you need to turn your plan into fruition. Contact us today or fill out our online form to schedule an appointment.